Product description

PN-600: Photo-Sensitive Film for Contact copying

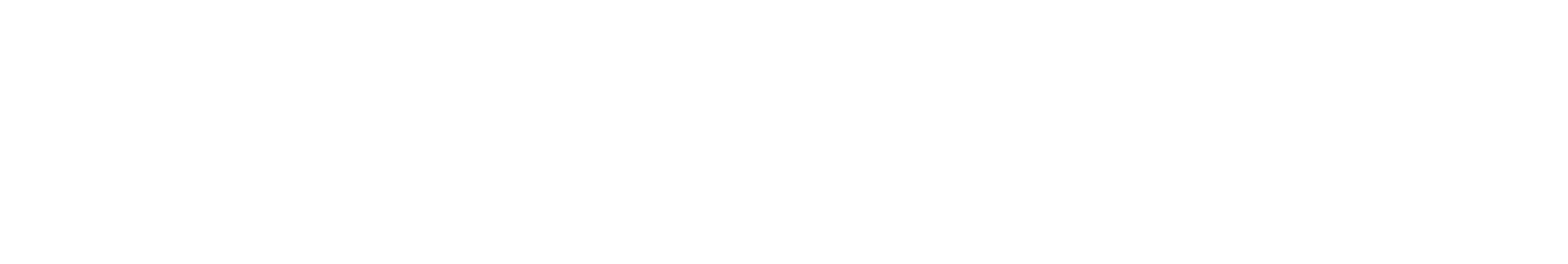

PN600 is a photo-sensitive film designed for contact copying, allowing both a positive and a negative copy of an original to be produced without the use of chemicals or a darkroom. The film is mainly used for transferring patterns to printed circuit boards, front panels, signage, and similar applications in electronics and graphic production. Exposure is performed using UV light, and the originals can be CAD prints, ink drawings, or photocopies on white paper. The product enables fast and accurate production of working originals for technical processes.

The film: Positive and Negative Copy in One Operation

The film consists of a 0.1 mm thick carrier coated with a photo-sensitive metallic layer and a thinner protective film. CAD-generated originals (on white paper or matte film), rub-on transfers, photocopies (white paper), or ink drawings can be used. No chemicals are required for development or fixing after exposure. A darkroom is not necessary. Note that the film can be handled under dim light for short periods (approx. 1–2 minutes), but it is sensitive to regular white light, daylight, and especially UV light.

Positive + Negative Copy

After exposure using a contact printing method, both a positive and a negative copy of the original are obtained. The carrier yields the positive copy, while the thinner protective film provides the negative. Due to its low thickness, the negative copy is somewhat fragile. If it is to be used, it is recommended to mount it onto a clear film (e.g., drafting film) before removing it from the carrier.

Exposure

Exposure is done using UV light (wavelength 350–370 nm). The photo-sensitive side of the film has a light blue tint and should face the light source during direct copying. Exposure time is short. With a 60 W UV exposure unit, 5 seconds yields excellent results. Overexposure can cause "stick," where narrow traces become thinner than in the original.

A more even and controllable exposure can be achieved by using matte mounting film or white paper as a filter. This allows for a longer exposure time without risk of overexposure. Layouts, CAD prints, or photocopies on white 60–80 g paper can be used directly. Use a glass sheet to press the film flat and ensure good contact. To facilitate removal of the thin protective film, mask a small section of one corner using masking tape.

Development

After exposure, gently scrape a corner on the blue-tinted side (e.g., where the masking was placed). The thinner, blue-toned film will come loose and can be carefully removed from the carrier. The negative image will remain on this film, while the carrier provides a perfect positive copy. Both can be used immediately for further production of PCBs, front panels, labels, gobos, or similar items.

If the negative copy is to be used, it is recommended to reinforce it with self-adhesive clear film or similar material to increase its stiffness and ease of handling. If the positive copy appears blotchy or speckled – increase the exposure time. If traces or images disappear when separating the layers – reduce the exposure time.

Paper Quality

Different original materials require different exposure times. It is advisable to perform a test exposure with a small piece of the film to find the optimal result. Below are examples of materials and their required exposure times (UV exposure unit 30–60 W):

Clear film: 3-4 seconds

Multi Copy (157.066) - 15 minutes

Multi Copy 80 (154.806) - 6 to 7 minutesminuter

Brilliant Copy 901154 - 2 to 3 minutesminuter

When using UV LEDs, the exposure time may need to be increased depending on the LEDs’ intensity and beam angle.